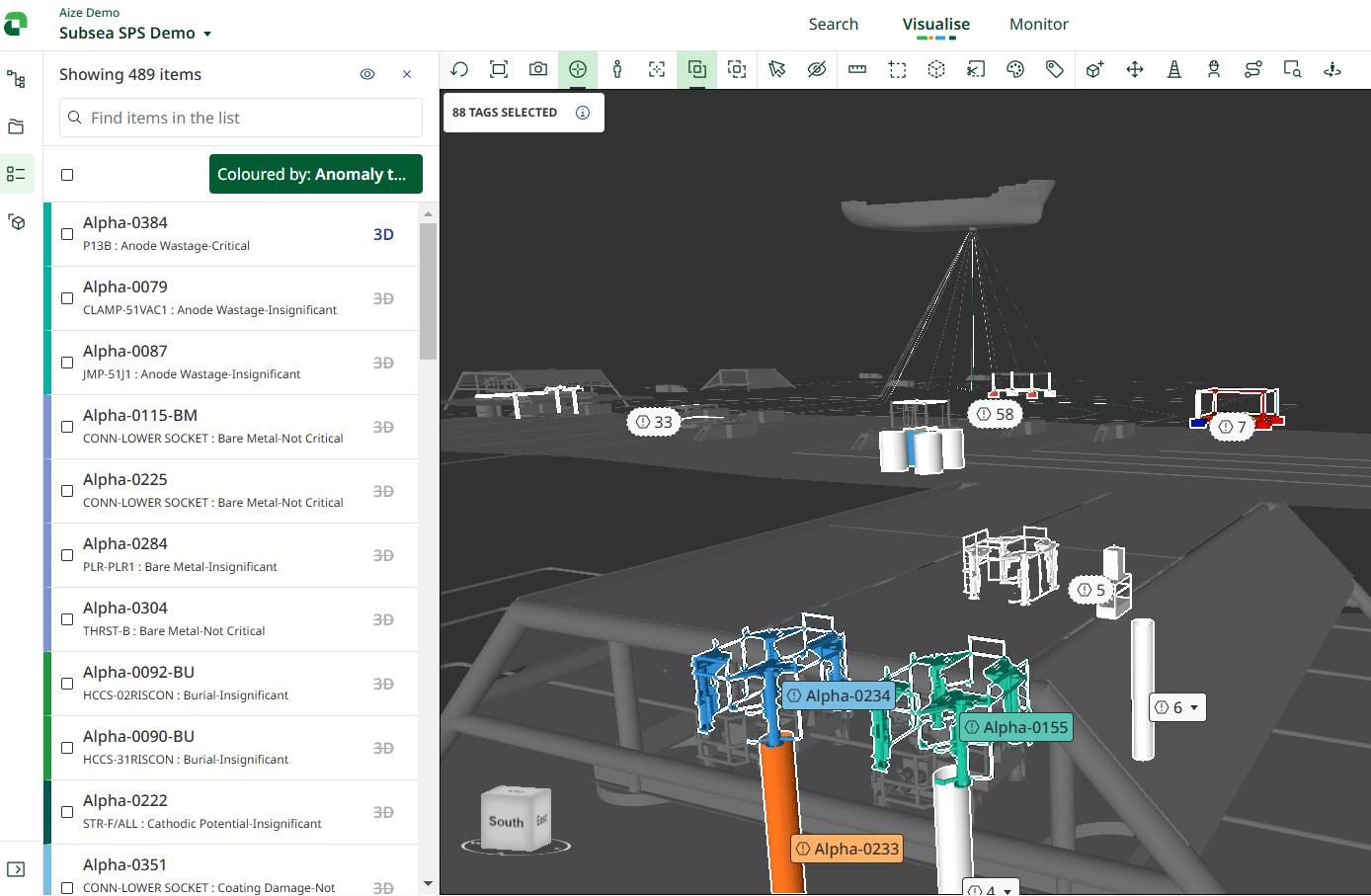

Visualising the distribution of integrity data, or any other data, across your subsea facility can turbocharge how you take insights to identify risk and opportunity. With the right tools, you can visualise your data in multiple ways that empower you to make better decisions.

Subsea engineers and teams face the reality of working with assets they can't physically access throughout their entire lifecycle. The only way to inspect these critical components involves deploying costly Remote Operated Vehicles (ROVs) and Dive Support Vessels (DSVs) for planned inspection campaigns. These operations are not only expensive but also logistically demanding.

This is where Aize steps in, revolutionising the way subsea teams operate by offering an innovative digital solution that reduces costs, improves efficiency and enhances safety.

This approach allows you to see the context that matters most to you, with all your data centralised. You can dive into the details to become better informed, spot opportunities, and make smarter decisions. Collaborate with colleagues and contractors in one place to maintain a shared understanding of the current status and the plan. Be more informed about your facility and work more efficiently.

Optimising Inspection Campaigns

Traditionally, inspection campaigns involve the use of ROVs to visually assess subsea equipment. Managing your integrity data in dedicated systems like Integrity Elementz is key to making this data available and useful. The next step towards optimised subsea field management is in unlocking collaboration planning. With Aize, engineers can now visualise data in the context of the entire facility—whether in 2D or 3D models. This allows for precise identification of key areas needing inspection, ensuring more focused and effective ROV dive planning.

By integrating the 3D model, teams can pre-plan inspection routes with anomalies highlighted on the model, enabling discussions before the dive. This collaborative approach ensures that the scope of the inspection is thoroughly prepared, reducing the time and cost of ROV dives. Aize allows users to identify other equipment or areas of the facility that may benefit from inspection during the same dive, avoiding the need for future dedicated campaigns.

This capability leads to significantly reduced dive times and earlier vessel release, resulting in substantial cost savings on vessel hire - a potential game-changer for subsea operators looking to optimise without compromising on safety or performance.

Click the Vimeo icon at the bottom right to watch in full-screen:

Accessing and Utilising Data More Effectively

One of the perennial challenges for engineers in operations is locating the data they need - whether for planning, ongoing operations, or troubleshooting. Aize transforms this experience by drastically cutting the time it takes to find crucial equipment information, documents, and anomaly reports. The software's smart interface allows users to easily navigate a facility’s layout, access equipment specifications, and view all relevant documents, including design data and historical records, in a split-screen format that combines 3D models and documentation.

This streamlined access to information means that engineers can make informed decisions faster, improving their ability to monitor the health and vulnerability of their assets. By leveraging existing data and media—such as video footage and historical documentation—Aize reduces the need for costly ROV dives, as teams can assess equipment conditions remotely using smart data aggregation tools with the confidence that historical data is available in one place and not lost. Furthermore, accessing information quickly and easily during high-stress situations that are impacting production can not only ease this stress but also enable a faster return to the facility being online.

Delivering Value Through Efficiency

By empowering engineers to work more effectively, Aize unlocks significant value for subsea operations. The ability to quickly locate and interpret data leads to better monitoring, faster issue resolution, and overall improved equipment health management. As subsea teams become more data-driven, they also become more proactive, reducing the risk of equipment failure and improving the reliability of subsea assets.

Aize is a catalyst for smarter, safer, and more cost-effective operations in the most challenging environments. Whether it's optimising inspection campaigns or making data easier to find and use, Aize is helping transform the future of subsea technology.

Want to see what else Aize can do?

Learn more on our Aize for Subsea Page

Post written by Tom Brian

Tom is our Group Product Manager and has previous worked for TotalEnergies in drilling and wells for 14 years in various roles across engineering, operations and leadership before joining Aize in product management. He has a passion for running, cycling and generally being outdoors.

Stay in the loop

I’d like to sign up to Aize newsletter