Operators who handle subsea fields do so in the most challenging environments, where extreme depths, harsh conditions, and limited visibility often push traditional operational methods to their limits. All at high cost and high risk. The rise of digital technology presents transformative opportunities for subsea operators, enabling them to overcome these challenges while driving efficiency, safety, and innovation.

We’ve gathered 12 high-level examples of the value digital technology brings to subsea operations and why it is key to the industry's future.

1. Improved safety in hazardous environments

Safety is paramount where risk of major loss of containment is always present. Digital solutions now offer continuous monitoring, ensuring that safety standards are adhered to at all times. Current alerts, automated safety checks and model driven failure prediction help reduce the risk of accidents, providing a virtual safety net that can catch potential issues before they escalate.

2. Cost savings

Operational costs in subsea operations are high, from hiring dive support vessels to performing routine inspections. Digital solutions optimise field work execution, directly reducing the duration of high-cost vessel days. For example, by consolidating inspection campaigns and minimising dive times, digital tools can drastically cut costs associated with vessel hire and associated resources.

3. Faster, data-driven decision-making

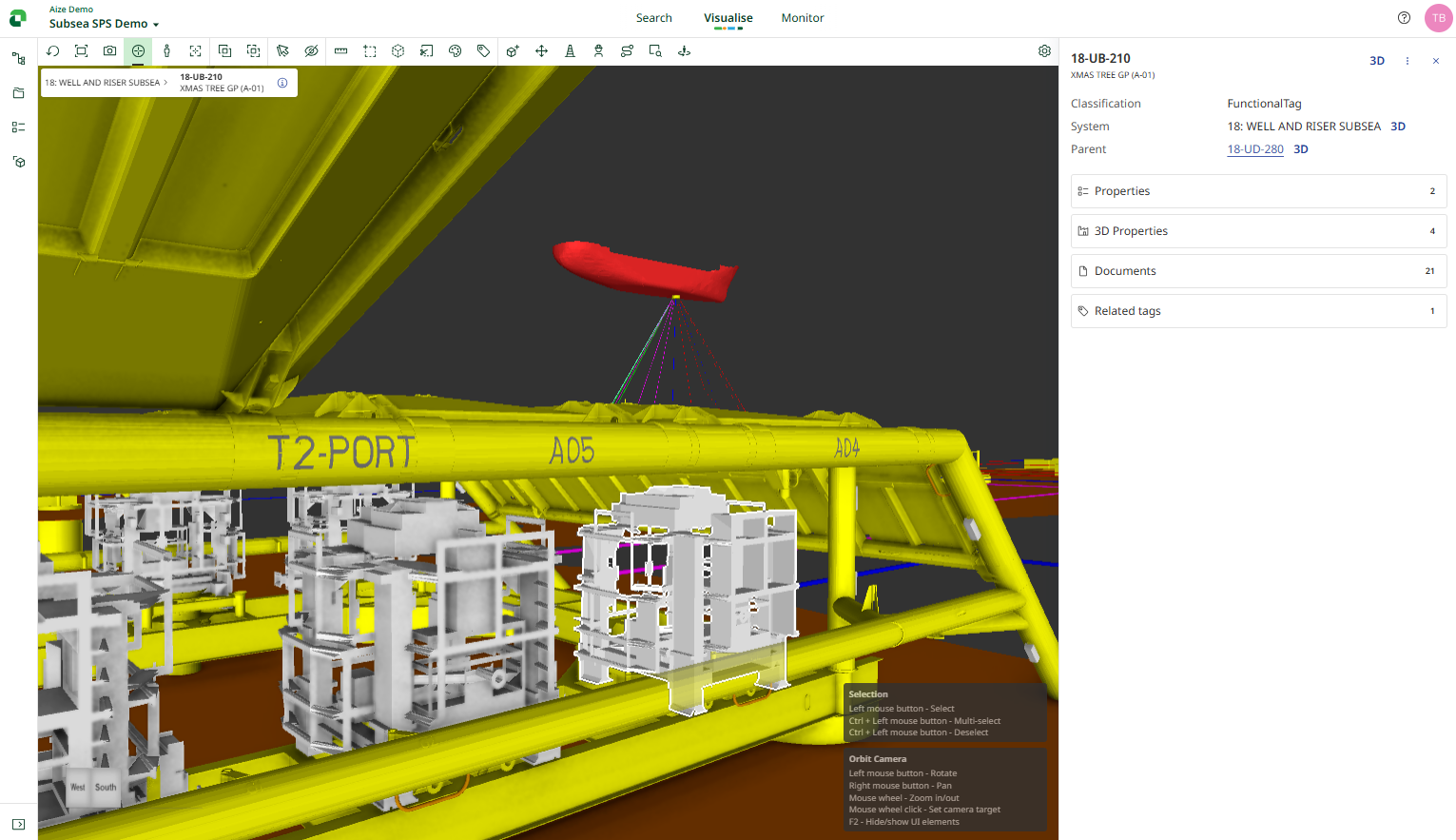

The integration of all relevant data into a single software product can be a game changer for subsea teams. With quick access to current and historical data, teams can make informed decisions faster. Whether it's assessing anomalies or planning interventions, the ability to pull up a comprehensive view of the facility and its data accelerates the decision-making process and reduces downtime.

4. Data consolidation for better risk management

Subsea operations involve vast amounts of data from various sources—inspection reports, ROV footage, equipment specs, and more. Digital products bring all this data into one place, improving accuracy and availability. This consolidation is especially critical in risk assessments and operational planning, as it enables teams to see the bigger picture and make proactive decisions to mitigate risks.

5. Enhancing collaboration across teams

Subsea projects often involve multiple teams, third-party contractors, and stakeholders, all of whom need access to the same information. Cloud-based digital software make data sharing seamless, ensuring everyone is on the same page. This enhanced collaboration across the asset management spectrum improves operational efficiency and ensures that everyone is working from the same set of accurate data.

6. Leveraging lessons learnt

In subsea, learning from past incidents can prevent future problems. Digital systems not only store historical data but also make it easier to access and analyse. Harnessing the experience that is trapped in data to ensure lessons are learnt for a continuous improvement and no repeated errors.

Click the Vimeo icon at the bottom right to watch in full-screen:

7. Reducing inspection times

Traditional inspection methods in subsea environments are time-consuming and expensive, often taking months to complete. Digital techniques like flooded member detection have revolutionised these processes, reducing inspection times from months to mere days. This not only improves efficiency but also minimises operational downtime, saving both time and money.

8. Minimising human error

Automation is a key benefit of many digital platforms. By automating data entry, inspections, and other operational processes, these tools drastically reduce the likelihood of human error. This is especially important in subsea environments, where even minor mistakes can lead to costly and dangerous outcomes.

9. Increasing data reliability

Technologies like digital twins create a reliable, consistent virtual representation of physical assets, ensuring the accuracy of data used in operational decisions. The reliability of this data helps subsea operators maintain a high standard of performance and reduces the likelihood of equipment failure.

10. Enabling predictive maintenance

Predictive maintenance is one of the most valuable contributions of digital technology to subsea operations. By analysing current data, digital platforms can predict when equipment is likely to fail, allowing teams to address issues before they lead to costly downtime. This extends the life of subsea equipment and improves overall operational efficiency.

11. Improved data traceability

In subsea operations, data integrity and traceability are essential for compliance and audits. Digital software ensures that actions, decisions, and data changes are recorded and traceable. This is crucial for regulatory compliance and can also help operators demonstrate a clear record of operational integrity to stakeholders.

12. Remote operations and automation

Digital technology enables more remote monitoring and control, reducing the need for physical presence in hazardous subsea environments. This reduces risk to personnel, while also allowing operators to oversee multiple projects from centralised locations. The ability to operate remotely is particularly important for reducing costs and maintaining operations in difficult or dangerous locations.

Supporting innovation and the future of subsea

The adoption of digital technology opens the door for further innovations in the subsea industry. From AI-driven analytics to robotics, these innovations will continue to transform subsea operations. Digital software like Aize provides a strong foundation for integrating these advanced technologies, ensuring that subsea operators remain at the forefront of technological progress.

In a sector where safety, efficiency, and reliability are paramount, digital technology is redefining how subsea operations are managed. As the industry continues to evolve, the operators who leverage digital tools will be better positioned to reduce costs, mitigate risks, and embrace the future of subsea.

Want to see what else Aize can do?

Post written by Tom Brian

Tom is our Group Product Manager and has previous worked for TotalEnergies in drilling and wells for 14 years in various roles across engineering, operations and leadership before joining Aize in product management. He has a passion for running, cycling and generally being outdoors.

Stay in the loop

I’d like to sign up to Aize newsletter